Fiber testing

Fiber testing

Fiber Optic Testing

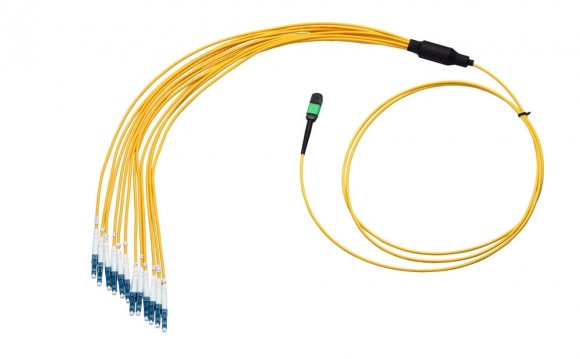

Fiber optics cabling is the core of today's datacom networks. Optical fiber is the predominant media type for mission-critical datacenter links, backbone within buildings, and longer distances for campus networks. As network speeds and bandwidth demands increase, distance and loss limitations have decreased, making fiber optic cabling certification more important than ever.

Inspecting Fiber Optic Cable for Light Loss

For decades, fiber optics have been inspected and cleaned to ensure the proper passage of light. While fiber optics inspection and cleaning fiber connectors is not new, it is growing in importance as links with increasingly higher data rates are driving decreasingly small loss budgets. With less tolerance for overall light loss, the attenuation through adapters must be lower than ever before. This can be achieved by properly inspecting and cleaning fiber optic cables when they are installed or while making moves, or changes.

There are two types of problems that will cause loss as light leaves one end-face and enters another inside an adapter: contamination and damage.

Dust, oils and water blocking gel are common forms of fiber connector end-face contamination. Simply touching the ferrule will immediately deposit body oil on the end-face, and cause unacceptable attenuation once connection are made. Dust and small static-charged particles float through the air and can land on any exposed termination. This can be especially true in facilities undergoing construction or renovation. In new installations, buffer gel and pulling lube can easily find its way onto an end-face.

Fiber optic cable damage appears as a scratch, pit, crack, or chip. These end-face surface defects could be the result of poor termination or mated contamination. Deciding to mate every connection first and then inspecting only those that fail is a risky approach as the physical contact of mated contaminants can cause permanent damage. This permanent damage would require more costly and time consuming re-termination or replacement of pre-terminated links.

From the first days of fiber optic cabling, stereo bench top microscopes were used to inspect fiber optic end-faces. Over time, smaller, portable microscopes were designed to easily test fiber cable. Microscopes can be divided into two basic groupings: optical and video. Optical microscopes incorporate an objective lens and an eyepiece lens to allow you to view the end-face directly through the device. Video microscopes incorporate both an optical probe and a display for viewing the probe’s image. Probes are designed to be small so that they can reach ports in hard-to-access places. The screens allow images to be expanded for easier identification of contaminants and damage. Because the end-face is viewed on a screen instead of directly, probes minimize the chance of a harmful laser light reaching a person’s eye. Fluke Networks offers a range of fiber optic microscopes from simple to professional-grade.

Cleaning Fiber Optic Cables

Because cleaning has been part of fiber optic cable maintenance for years, most people have their own approaches for cleaning end-faces, including some suboptimal approaches such as blasting the fiber optic cable with canned air, or using Isopropyl alcohol (IPA). Fiber-specific solvents are superior at dissolving virtually any contaminate lurking on a fiber end-face and have tailored evaporation rates that give them time to work yet disappear before mating. The most basic tools used are wipes and swabs used to clean patch cords and inside ports, respectively. Convenient fiber optic cleaning kits include all the solvent and cleaning equipment one needs for precision end-face cleaning.

Versiv Kit Configurator

How will you be using your Versiv?

Fiber Optics Testing: Troubleshooting, Verification, and Certification

Fiber optic testers include tools to perform basic inspection and cleaning, basic troubleshooting and verification testers, certification testers, and advanced OTDR testers for troubleshooting and analysis of existing cabling.

For simple fiber troubleshooting and verification testers, the SimpliFiber Pro and source solutions work together to measure multimode and singlemode fiber loss. Built-in results storage and automatic wavelength synchronization save time and prevent errors.

Certification of new cabling per IEEE, TIA/EIA, or ISO/IEC standards is necessary to ensure that the link will run the intended application. Complete fiber optic cabling certification includes two parts; Tier 1 or Basic Test Regimen and Tier 2 or Extended Test Regimen. Tier 1 fiber optic cabling certification is performed with a power meter and light source or optical loss test set such as the CertiFiber Pro to measure the absolute loss of the link and compare it to the limits in the standard. Tier 2 fiber optic cabling certification and troubleshooting can be performed with an OTDR such as the OptiFiber Pro OTDR.

Certification of fiber optic links requires the right testing equipment, detailed knowledge of installation and application standards, and the ability to document your test results. The CertiFiber™ Pro is a handheld fiber optic certification tester that quickly and easily certifies multi-mode and single-mode networks. One button measures fiber length and optical loss on two fibers at two wavelengths, computes the optical loss budget, compares the results to the selected industry standard and provides an instant PASS or FAIL indication. Test results can easily be saved and managed using included LinkWare Software.

Tier 2fiber optic certification

adds the use of an OTDR to loss testing to ensure the quality of individual components of the installed link. Learn more about OTDRs and tier-two fiber certification here.Fluke Networks is the market leader in enterprise

fiber optic testing equipment

, with a wide range of field-tough fiber optic testers to inspect, clean, verify, certify, troubleshoot fiber optic networks.YOU MIGHT ALSO LIKE